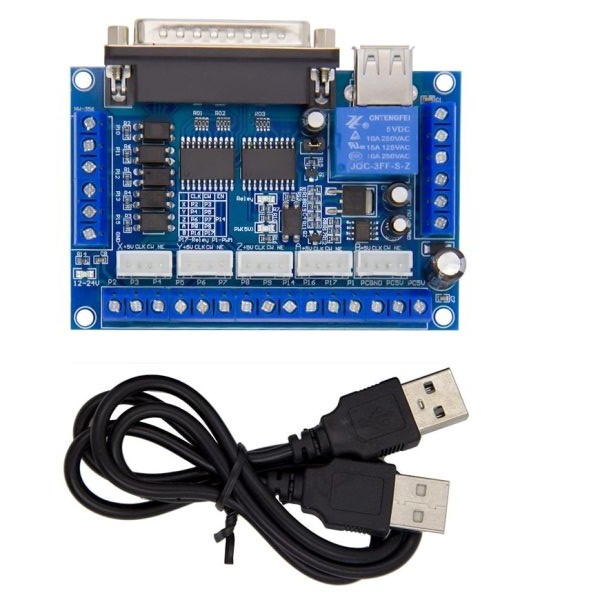

MACH3 Interface Board CNC 5 Axis With Optocoupler For Stepper Motor Driver

This content will be shared across all product pages.

An interface board for CNC systems typically serves as an intermediary between the computer (or controller) and various components of the CNC machine, such as stepper motor drivers, limit switches, and other peripheral devices. It facilitates the control and coordination of movements and operations with precision.

Key Features:

- Axis Support: Designed to control up to 5 axes (X, Y, Z, A, B).

- Compatibility: Often compatible with popular CNC control software like MACH3 or similar.

- Optocoupler: Includes optocouplers to isolate and protect the sensitive electronics from high-power components like stepper motor drivers.

- Inputs and Outputs: Provides inputs for limit switches (endstops) to define the working area limits and outputs for controlling stepper motor drivers.

- Power Supply: Typically operates on a 5V or 12V DC supply, depending on the specific board and components used.

- Connector Types: Utilizes standard connectors for easy integration with CNC machines and peripheral devices.

- LED Indicators: Includes status indicators to provide visual feedback on power and communication status.

- CNC Machines: Used in various CNC applications, including milling, routing, engraving, and other precision machining operations.

- Automation: Suitable for automated systems requiring precise control over multiple axes.

- DIY CNC Projects: Ideal for hobbyists and makers building their own CNC machines.

- Industrial Automation: Deployed in industrial settings for manufacturing and production processes.

- Robotics: Integrated into robotic systems for controlling movement and tasks.

- Dimensions: Varies by model and manufacturer.

- Power Requirements: Typically 5V or 12V DC input.

- Interface: Parallel or USB connection to the computer or controller.

- Compatibility: Compatible with various CNC control software and operating systems.

Technical Specifications:

- Logic Family: CMOS

- Number of Channels: 3

- Switch Configuration: Single-Pole Double-Throw (SPDT)

- Supply Voltage Range: 3V to 15V

- “ON” Resistance (R_ON): 125Ω typical at V_DD = 10V

- “OFF” Leakage Current (I_OFF): ±100pA typical at V_DD = 10V

- Control Input Voltage (V_IH): 0.7 V_DD min, 0.3 V_DD max

- Maximum Operating Frequency: 40 MHz at V_DD = 10V

Applications:

- Signal routing and switching

- Analog and digital multiplexing

- Audio and video signal processing

- Data acquisition systems

- Test equipment