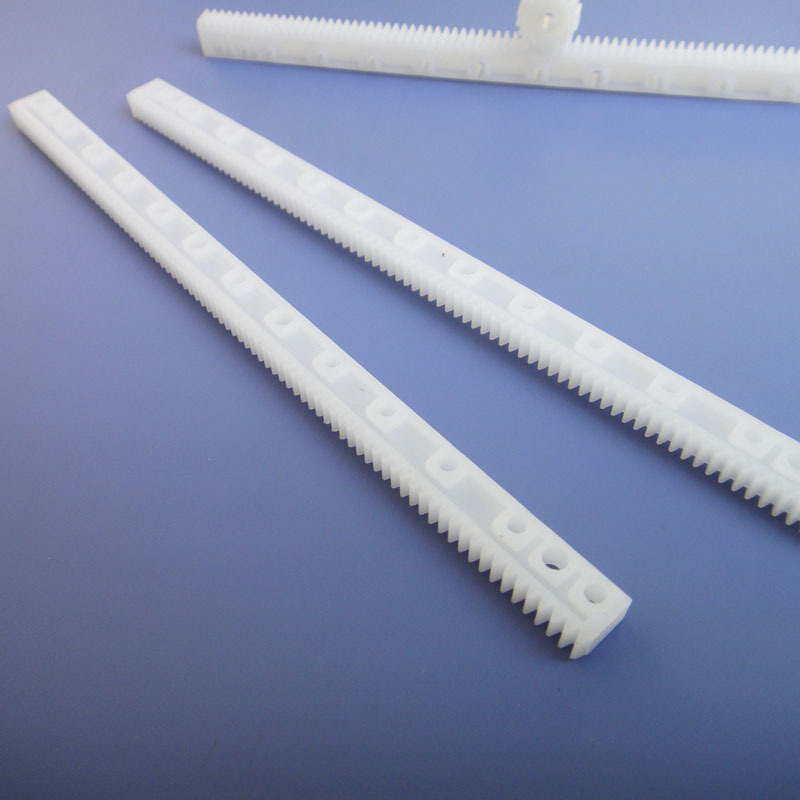

A Plastic Gear Rack is a linear gear component used in mechanical systems to convert rotational motion into linear motion. Made from durable plastic, this gear rack is suitable for applications where lightweight and cost-effective solutions are preferred. It is commonly used in automation, robotics, and model building to create precise linear movement.

Key Features:

- Material: Durable plastic for lightweight and cost-effective linear motion

- Gear Teeth: Machined with precision teeth for smooth and accurate motion

- Mounting: Can be easily mounted or integrated into various mechanical systems

- Versatile Use: Ideal for DIY projects, educational kits, and small machinery

- Compatibility: Designed to mesh with standard pinion gears for seamless operation

- Material: Plastic (often nylon or similar high-strength plastic)

- Length: Available in various lengths, typically from 50mm to 500mm

- Width: Typically ranges from 10mm to 30mm

- Tooth Pitch: Standard module or pitch depending on the design

- Tooth Profile: Straight or helical teeth, depending on application

- Mounting Options: Can be mounted using screws or adhesive, depending on the design

- Robotics: Used in linear actuators and motion systems

- Model Building: Ideal for models and simulations requiring linear motion

- Automation: Employed in conveyor systems and automated machinery

- DIY Projects: Suitable for hobbyists and educational projects involving linear motion

- Mounting: Secure the gear rack to the desired location using appropriate mounting hardware.

- Alignment: Ensure proper alignment with the corresponding pinion gear to achieve smooth operation.

- Integration: Connect the gear rack to the mechanical system or actuator to enable linear motion.

- Testing: Verify the movement and adjust if necessary to ensure accurate and smooth operation.

- Alignment: Proper alignment with the pinion gear is crucial to prevent misalignment and wear.

- Load Limits: Avoid exceeding the load capacity of the plastic gear rack to prevent deformation or failure.

- Handling: Handle with care to avoid damage to the gear teeth or the plastic material.