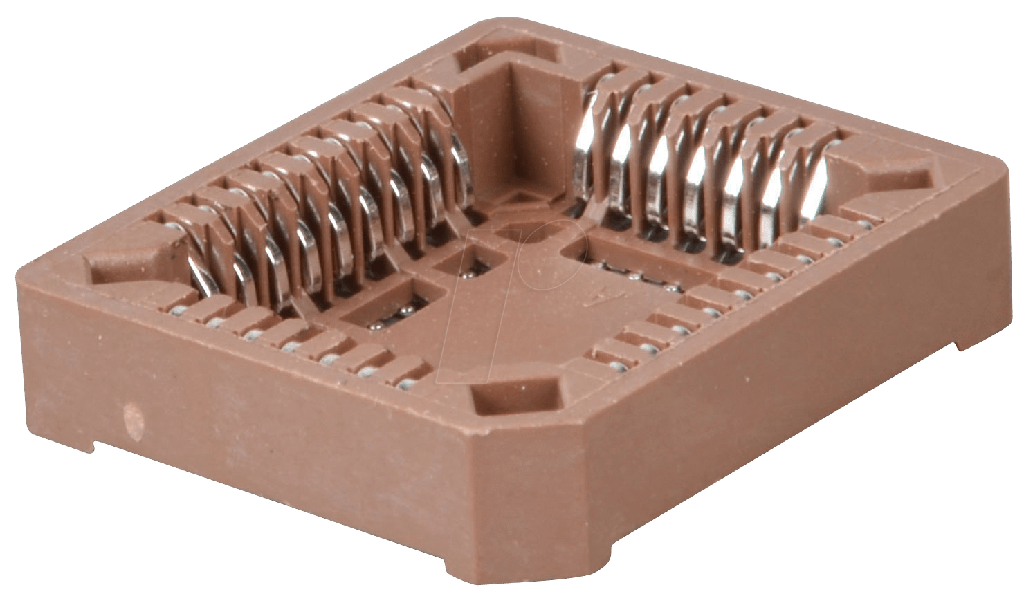

The PLCC32 IC socket is designed to accommodate 32-pin Plastic Leaded Chip Carrier (PLCC) integrated circuits. This type of socket provides a secure and convenient method to mount and replace PLCC32 ICs onto a printed circuit board (PCB), without the need for soldering directly to the IC pins.

Key Features:

- Compatibility: Supports 32-pin PLCC ICs

- Insertion and Removal: Allows for easy insertion and removal of ICs using a PLCC extraction tool

- Socket Type: Typically features a press-fit or soldered connection to the PCB

- Contact Material: Often utilizes gold-plated or tin-plated contacts for reliable electrical connections and corrosion resistance

- Housing Material: Constructed from durable plastic that can withstand soldering processes

- Mounting: Can be mounted onto the PCB using through-hole or surface-mount techniques

- Durability: Designed to withstand multiple insertions and removals of ICs without compromising the socket's integrity

- Pin Count: 32

- Pin Pitch: Standard 1.27 mm (0.05 inches) pitch

- Socket Type: Typically a press-fit or soldered socket onto the PCB

- Contact Material: Gold-plated or tin-plated contacts for enhanced conductivity and corrosion resistance

- Housing Material: High-temperature resistant plastic to endure soldering processes

- Dimensions: Specific to the 32-pin PLCC form factor, adhering to industry standards

- Prototyping and Testing: Ideal for development boards and prototypes where ICs need to be frequently replaced or tested.

- Repair and Maintenance: Facilitates the replacement of ICs in existing electronic equipment without soldering.

- Production: Suitable for low-volume production runs where ICs might need to be swapped out during assembly.

- Educational: Commonly used in educational kits and projects to demonstrate IC handling and replacement techniques.